Insulating walls and other surfaces is essential in numerous ways: It helps to inhibit heat flow, provide comfort, and ensure a warm environment. Reliable firms like Sky Chemical Services commence work after careful research. Their experts are well-informed and equipped with the latest tools and machinery. Energy efficiency, temperature control, noise reduction: benefits of effective wall insulation.

To maintain heat levels in a specific structure, different parameters have to be analyzed and implemented. Thickness is one of the most important ones. A thick layer provides a higher R-value, indicating better insulation. Increased thickness minimizes heat flow, enhances energy efficiency, and helps maintain desired indoor temperatures.

Heat Insulation and R-value

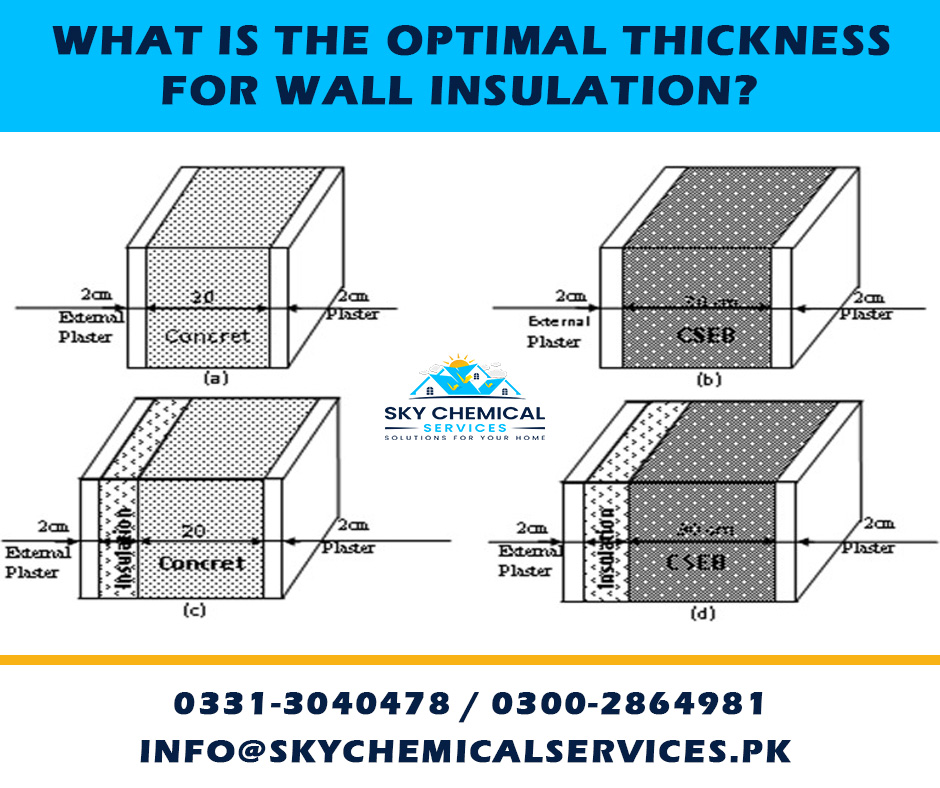

The optimal thickness for wall insulation depends on several factors, such as building design and insulation material. The goal is to achieve a balance between cost-effectiveness, energy efficiency, and space limitations.

Insulation is measured by its thermal resistance, known as the R-value. The higher the R-value, the better the insulation’s ability to resist heat flow. The recommended R-value for wall insulation varies across regions and building codes, taking into account local climate conditions. It depends on the type of insulation, density, and thickness.

Different R-values

In colder climates, a higher R-value and thicker insulation is recommended to minimize heat loss. Generally, an R-value of R-13 to R-21 is often suggested by experts.

In moderate climates, where heating and cooling needs exist, a lower R-value is sufficient. The optimal thickness is determined by balancing energy efficiency and cost considerations. An R-value of R-11 to R-15 is recommended for wall insulation. Lastly, in hot climates, an R-value of R-3 to R-6 is preferred.

Types of Insulation

Different insulation materials have varying R-values per inch of thickness. Common insulation materials for walls include fiberglass, cellulose, spray foam, and rigid foam.

Following are the R-values of heat insulation materials:

- Fiberglass insulation – R-3.5 per inch

- Cellulose insulation – R-3.7 per inch

- Spray foam insulation – R-3.5 to R-7 per inch

- Rigid foam insulation – R-4 to R-8 per inch

When determining the optimal thickness for wall insulation, it’s essential to consider the R-value and the available space within the wall cavity. Thicker insulation may require wider wall cavities or the need for special framing techniques to accommodate the additional thickness.

Tips to Manage Wall Insulation

It’s crucial to ensure proper installation to maximize the insulation’s effectiveness. Gaps, voids, or compressed insulation can reduce its thermal performance. Hire a professional installer or the manufacturer’s guidelines to achieve the desired insulation thickness.

To manage wall insulation, consider the following tips:

- Define the optimal insulation thickness based on pertinent factors.

- Select wall-insulation materials with suitable R-values per inch.

- Conduct an energy audit to identify areas of heat loss or gain; seal air leaks to prevent energy losses within the structure.

- Consider the orientation and design of the building to optimize insulation effectiveness.

- Inspect insulation for signs of damage or degradation. Address them quickly.

- Stay informed about advancements in insulation technology.

- Consult with professionals on insulation choices and installation techniques.

- Follow manufacturer guidelines and local building regulations for a compliant and efficient insulation system.

Conclusion

One of the most important aspects for wall insulation is R-value. It is the measurement of a sheet’s ability to restrict heat flow. R-values range from 1.5 to 7. The greater the number, the more effective the insulation. The optimum thickness for wall insulation depends on factors, such as climate, insulation material, and building design. Consult local building codes and professionals from Sky Chemical Services to determine the recommended thickness for effective insulation.